SMART WARDROBE

product design exploration

OVERVIEW

- Motivated by the challenge of locating items without creating closet clutter, this project explores a smart wardrobe concept.

- Defined the industrial design and core mechanism architecture.

- Integrated DFM/DFA into the mechanical design to ensure manufacturability, ease of assembly, and a smoother user experience.

- Implemented a camera‑equipped rail with MediaPipe‑based vision to identify garments, plus a web app to browse the catalog and compose OOTD looks.

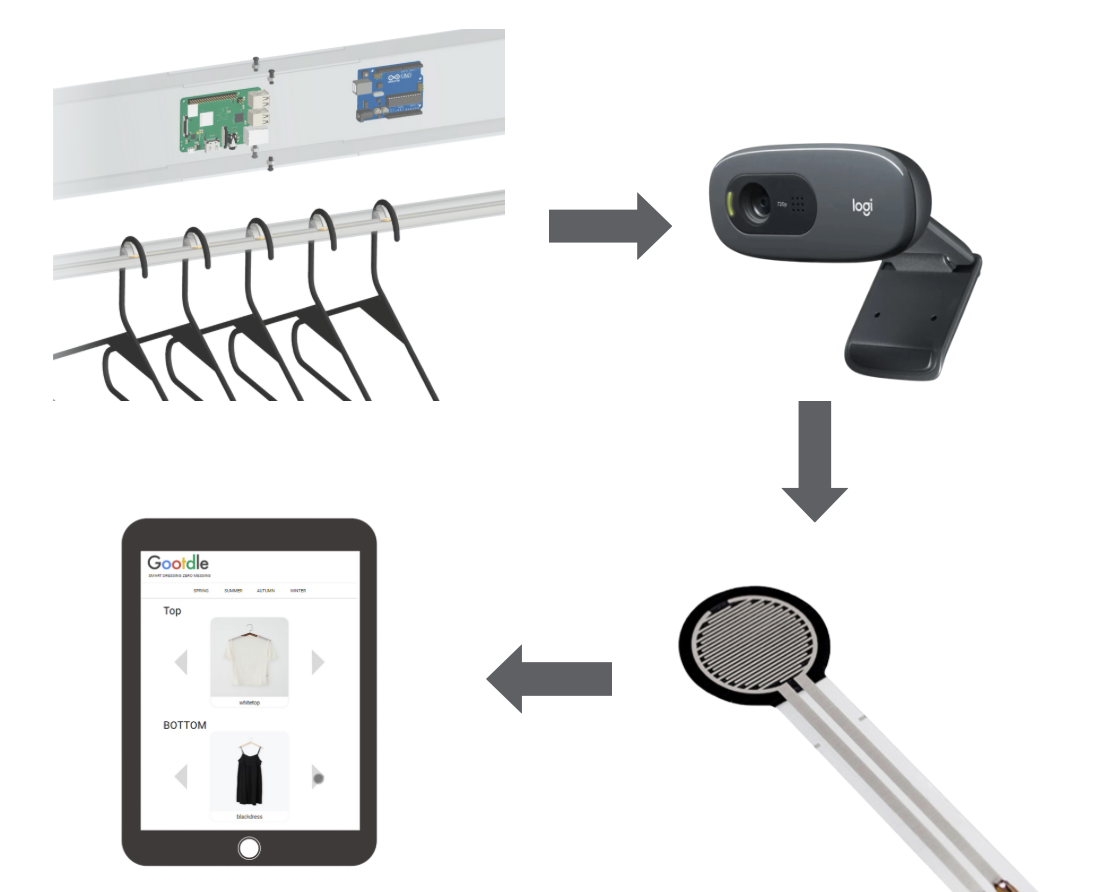

HOW IT WORKS

- A camera captures garment images when items are placed on the rail; the vision pipeline extracts features and assigns an ID.

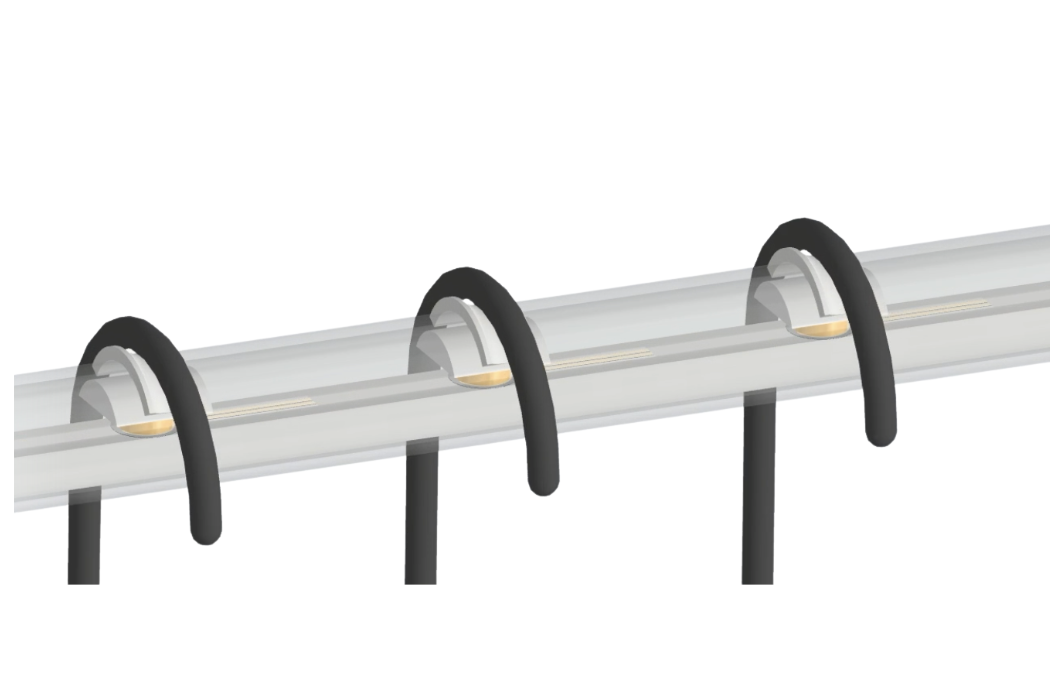

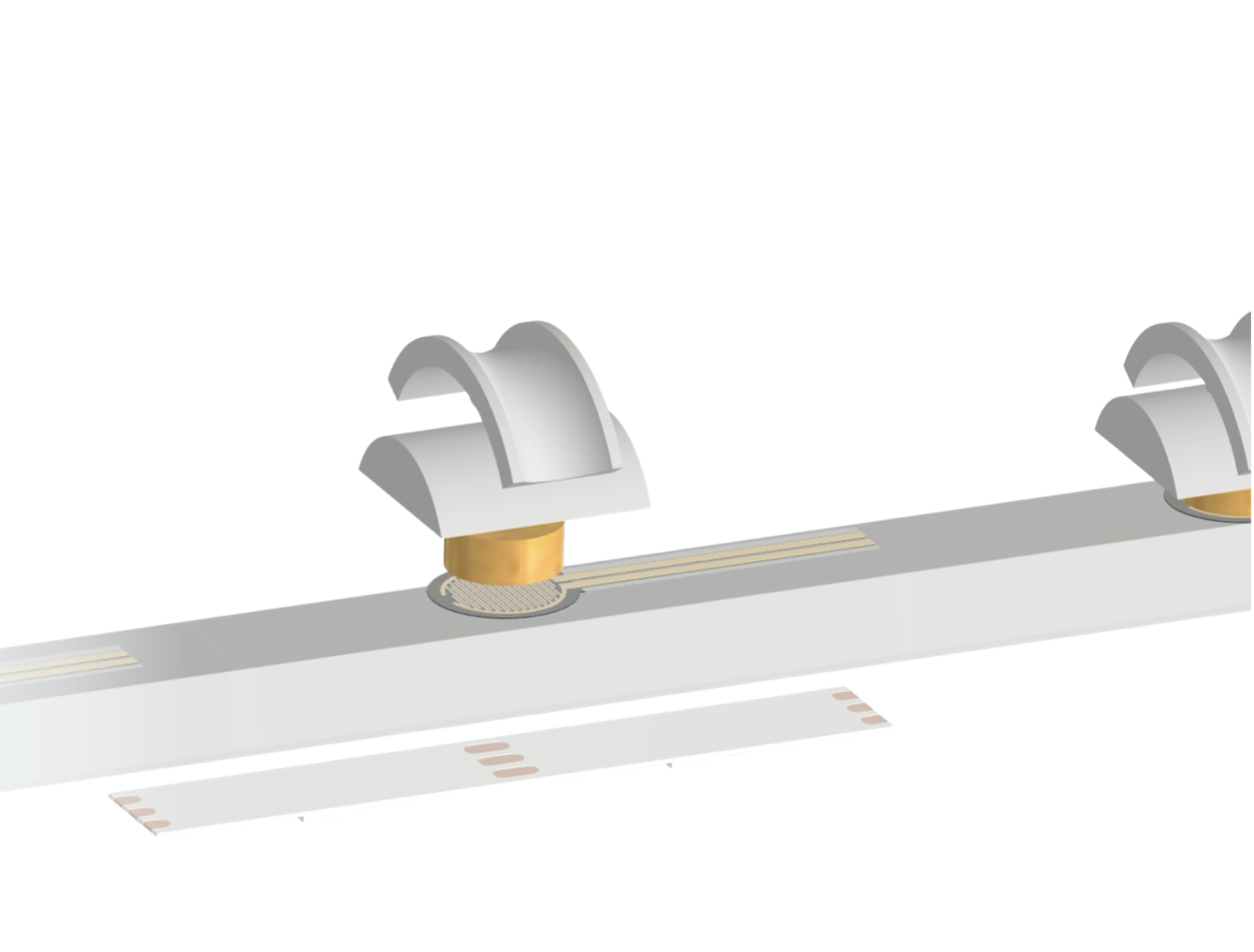

- A pressure sensor integrated with the rail provides a position index, allowing the system to localize each garment.

- The mapping between physical position and the digital catalog powers search and a simple web interface for browsing and outfit planning.

FIRST PROTOTYPE

- PVC is opaque, making indicator LEDs difficult to see.

- Cutting slots is challenging and must be repeated for each one.

- Assembly of the internal mechanism must be done individually.

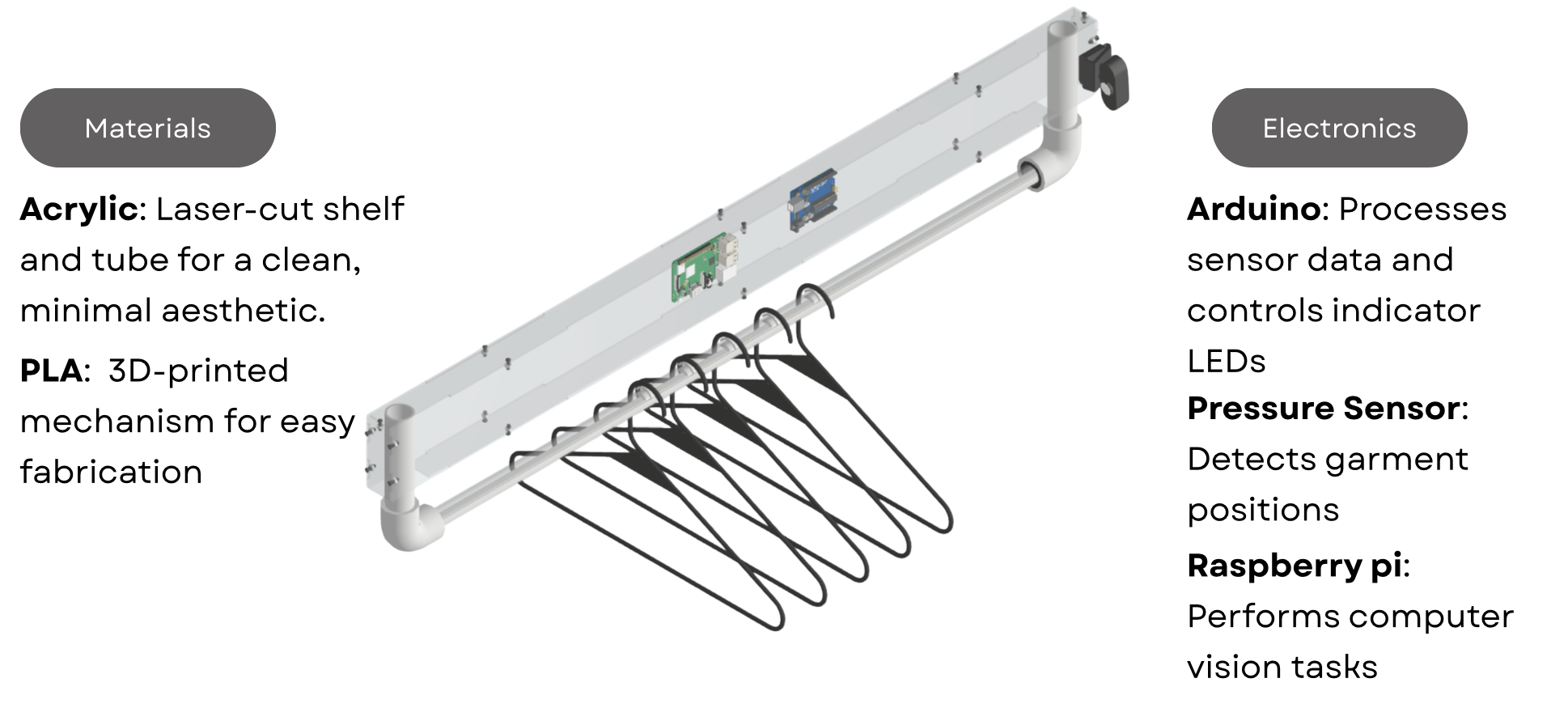

FINAL DESIGN

- Replaced single indicator LEDs with an LED strip for simpler manufacturing and control.

- Switched from PVC to acrylic to improve LED visibility.

- Integrated a PVC cable duct (PVC wire channel), allowing the entire mechanism to slide in as one unit for faster assembly and easier maintenance.

- Reinforced the acrylic using the PVC cable duct to increase structural strength.

- Reduced drilling to a single hole for the 3D‑printed slot to transmit force to the sensor.

RECOGNITION

- Awarded the Best Wanted Product at the Google Taiwan Hardware Product Sprint.

- Collaborated with teammates from diverse backgrounds to prototype and present the concept.