MEDICINE SORTING MACHINE

microcontroller & digital circuit

OVERVIEW

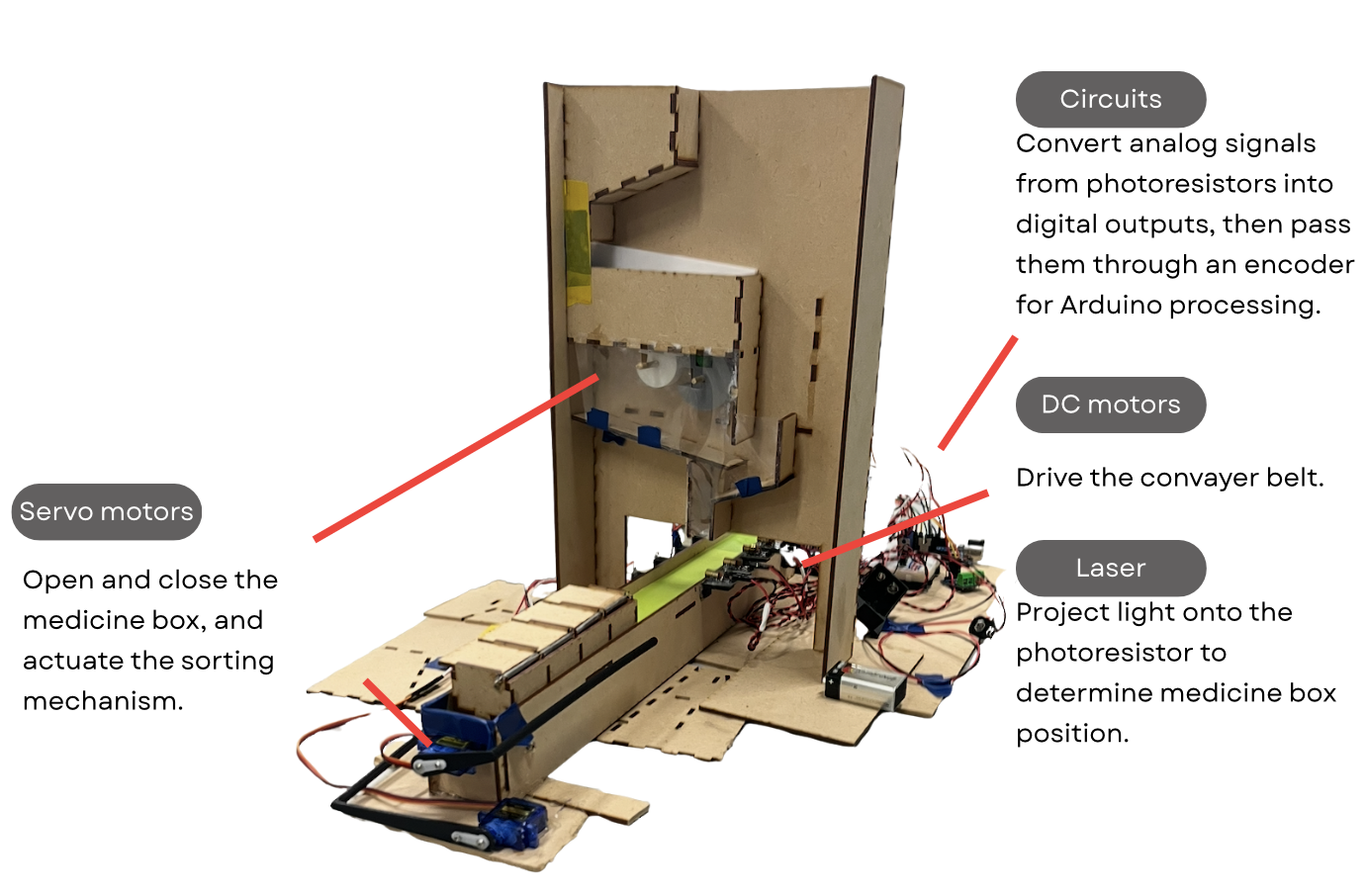

- Automated daily pill sorting to prevent missed doses across four time slots (morning, noon, evening, bedtime).

- Designed a low-cost dispenser that identifies the active slot, dispenses the set number of pills, and returns to home.

- Developed a cartridge and track system with a geared wheel for single-pill dispensing, adaptable with hole sizes for different pill types.

- Implemented drivetrain with TT motor for track movement; servos for opening/closing the cartridge lid; distance/laser sensors and photogates for position detection.

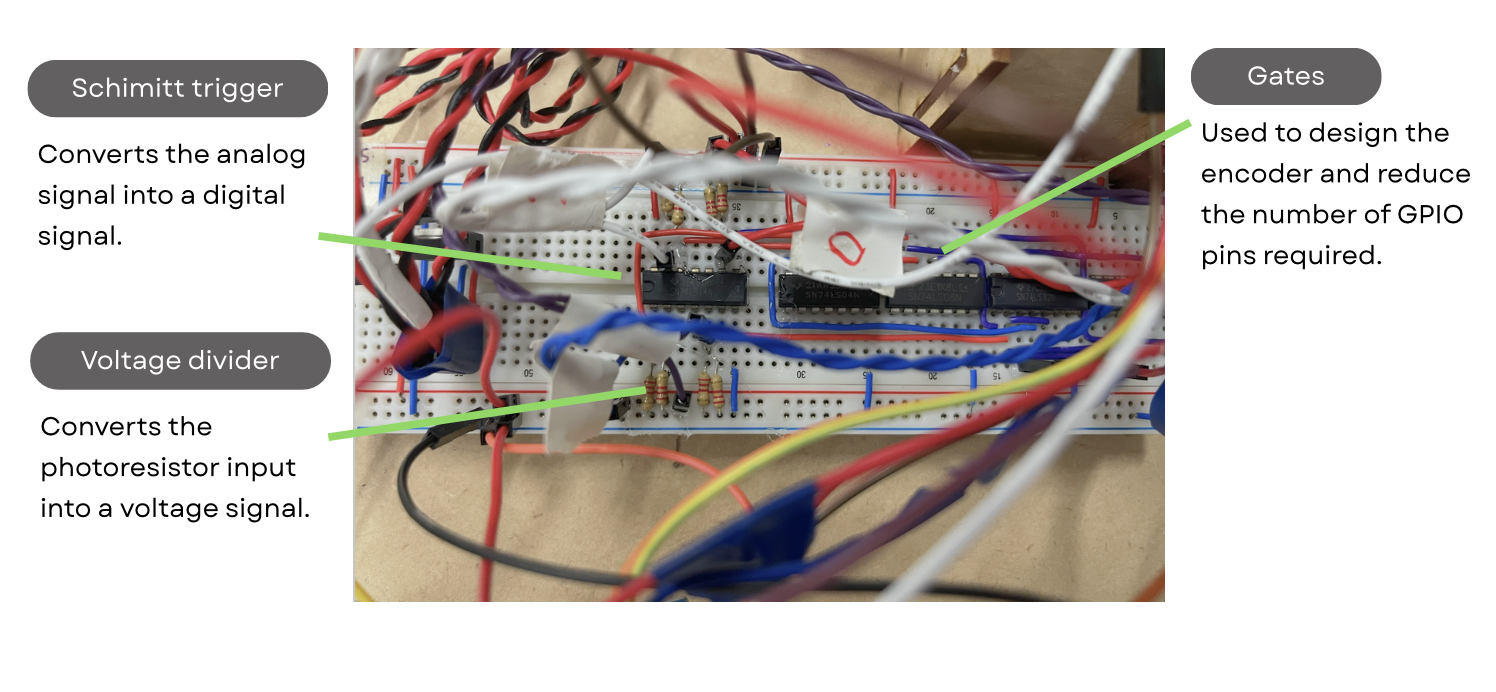

- Programmed Arduino controller with keypad interface; added logic circuit with Schmitt trigger to encode four photogate signals into digital inputs.

CIRCUIT DESIGN

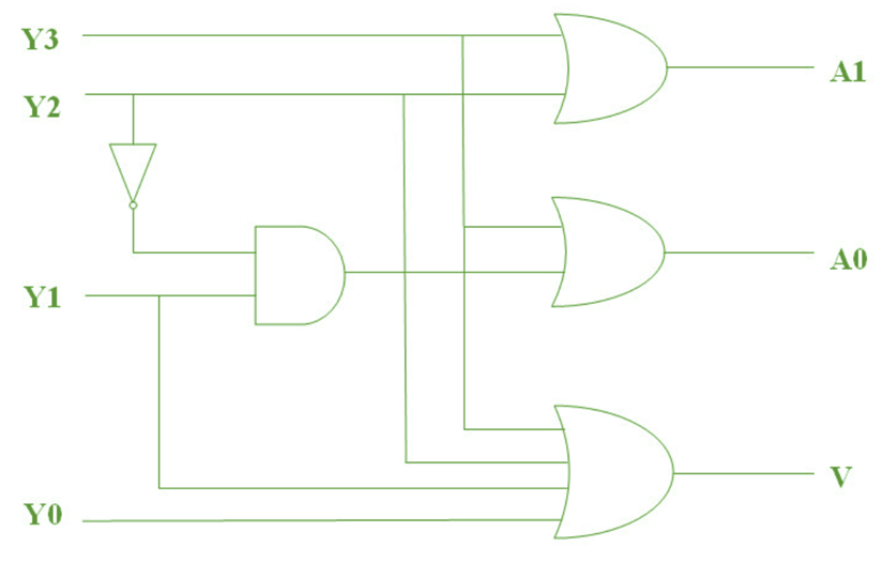

ENCODER LOGIC DIAGRAM

CIRCUIT LOGIC

Four photogate signals (Y3…Y0, 1 = light, 0 = blocked) are encoded to digital outputs (A1, A2) with a validity flag (V):

| Y3 | Y2 | Y1 | Y0 | A1 | A2 | V |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | x | x | 0 |

| 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| 1 | 1 | 0 | 0 | 0 | 1 | 1 |

| 1 | 0 | 0 | 0 | 1 | 0 | 1 |

| 0 | 0 | 0 | 0 | 1 | 1 | 1 |

CONTROL LOGIC

- Home: Return carriage to start (TT motor for a fixed duration) and confirm with sensor.

- Open: Servo opens cartridge lid.

- Select slot: Read encoded photogate state → active time slot (morning / noon / evening / bedtime).

- Dispense: For the entered dose count, rotate the geared wheel to drop pills one by one (A/B types supported).

- Advance: Drive to the next slot; repeat until all scheduled slots are served.

- Close: Servo closes lid and return to home.

DEMO VIDEO

SUMMARY

- Built a working dispenser with reliable position sensing and per‑slot dosing.

- Next: add basic machine vision for pill classification, increase supported medicines, integrate reminders, and support multiple cartridge types.