INTRODUCTION

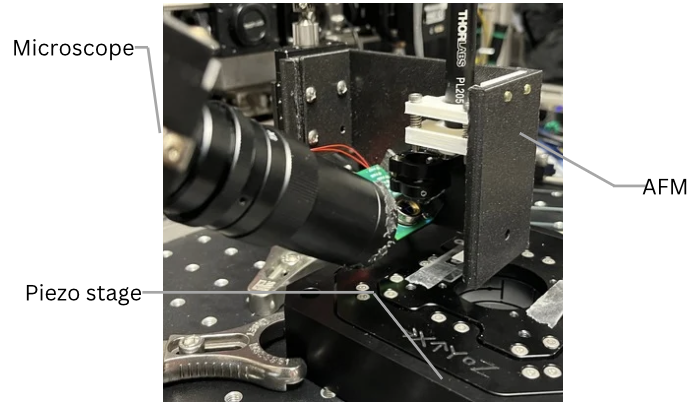

- 3D printing enables fast iteration of custom components. We designed and assembled a compact AFM (Atomic Force Microscope) to evaluate the feasibility of low‑cost fabrication for precision instruments.

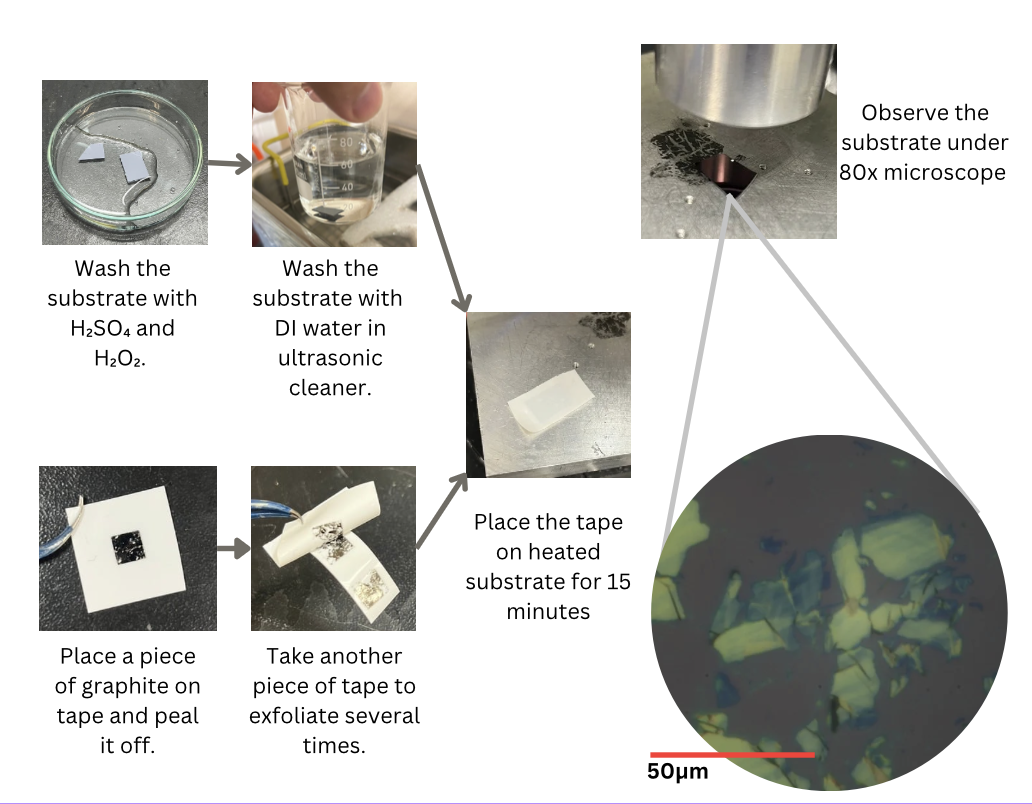

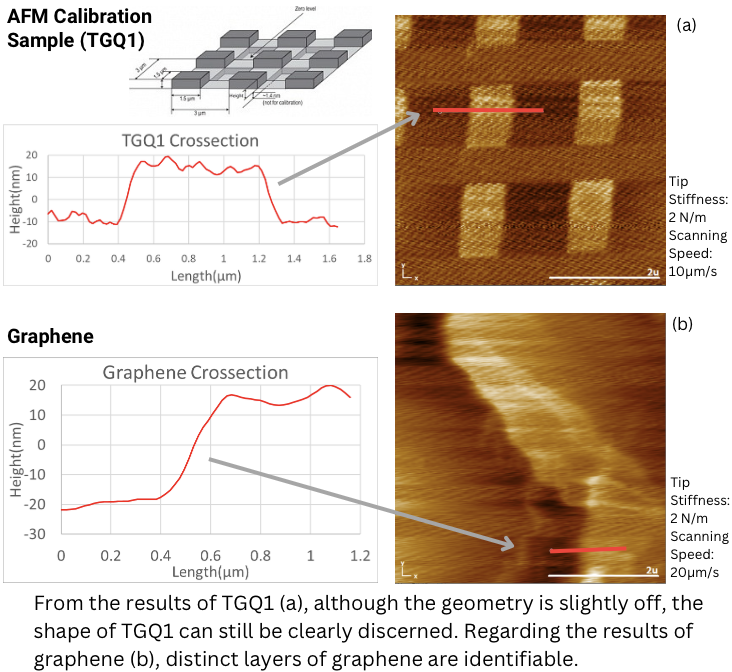

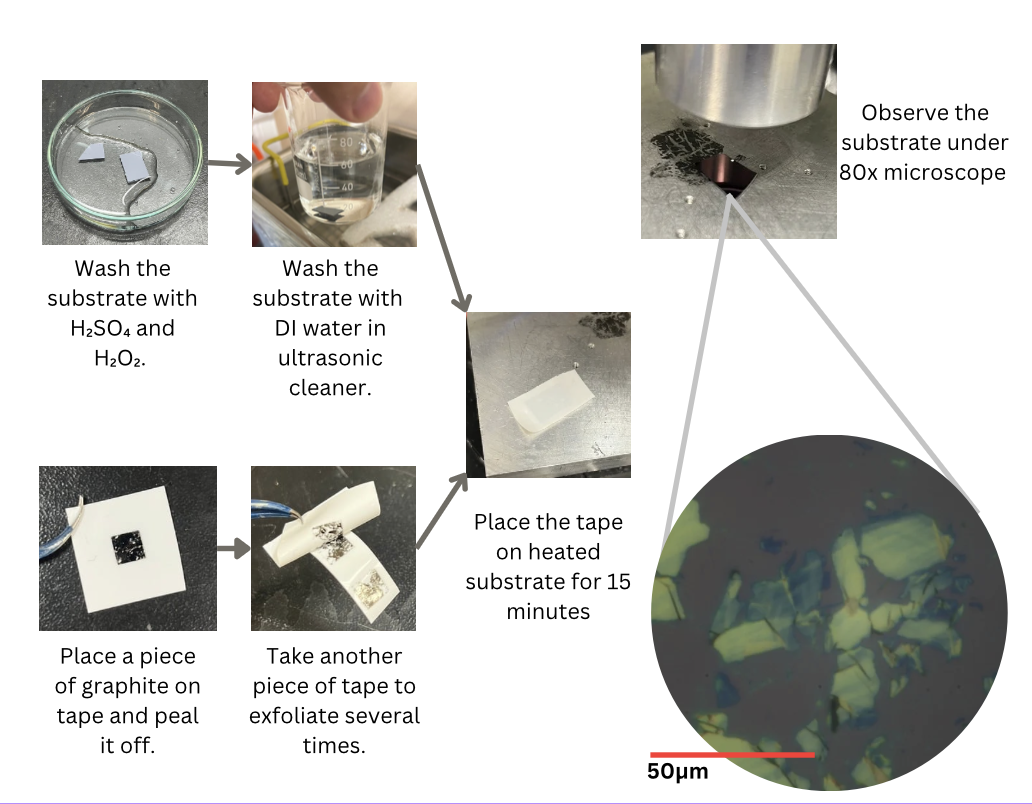

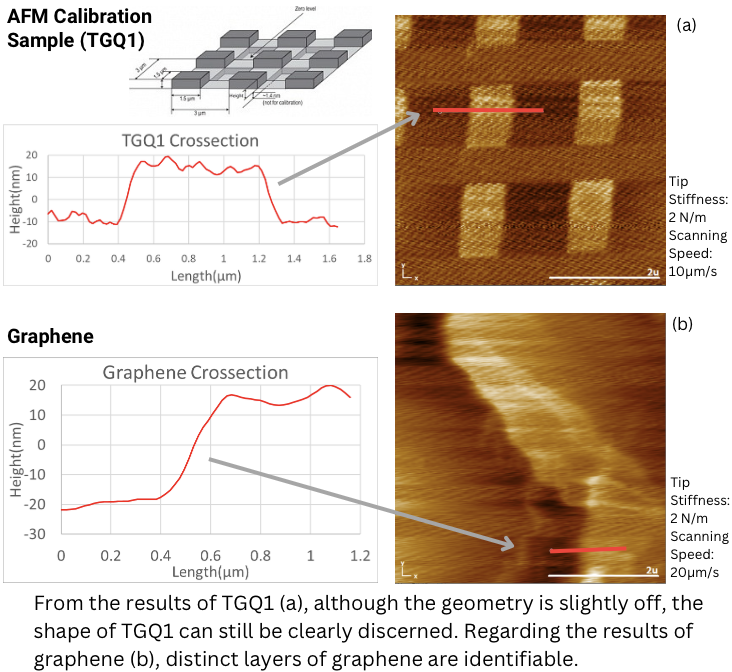

- Validation used a commercial calibration grating (TGQ1) and tape‑exfoliated graphene.

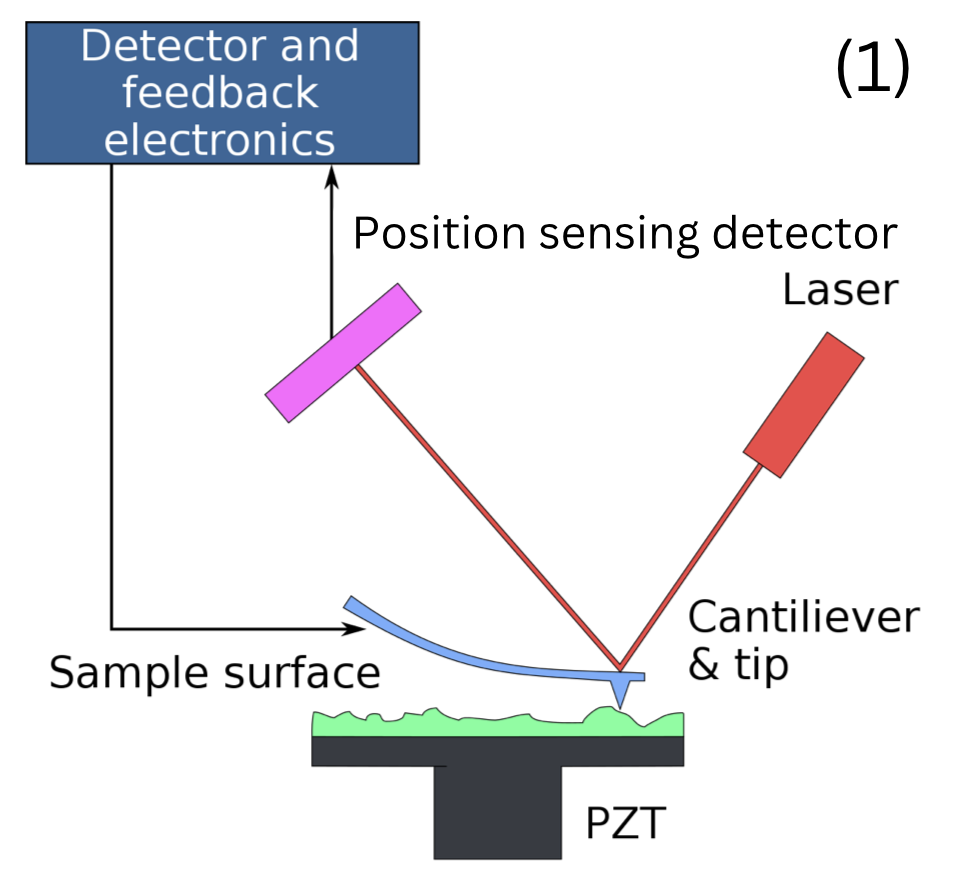

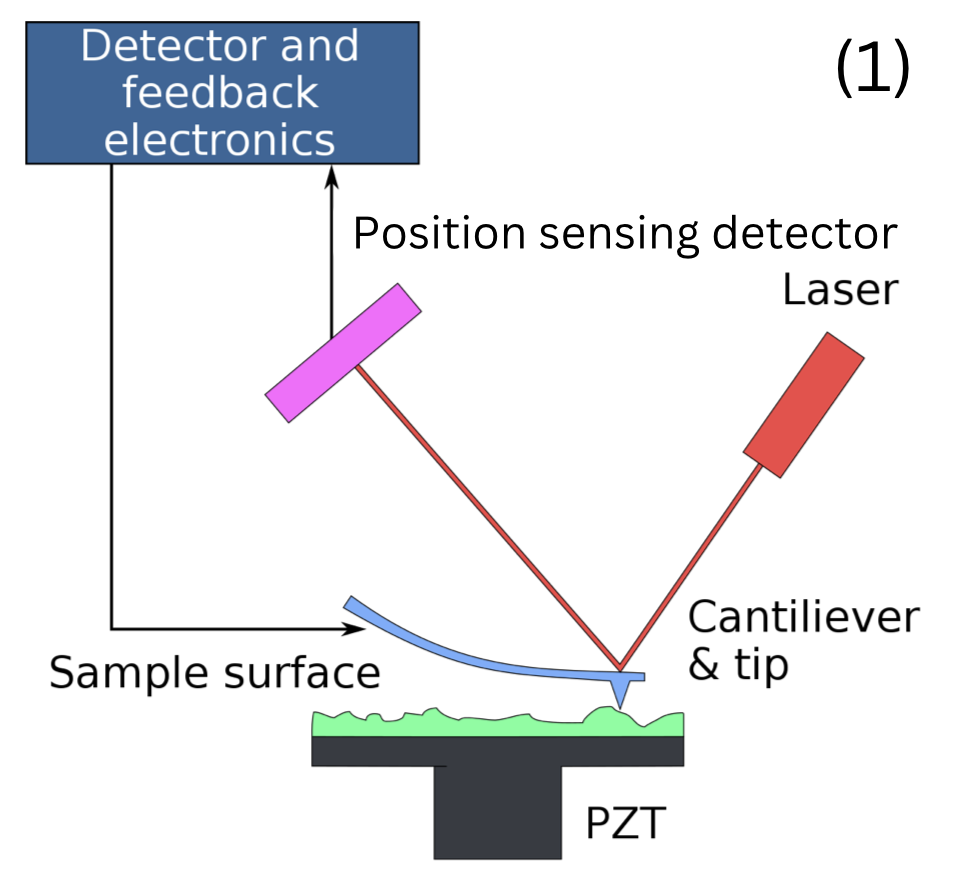

WHAT IS AFM?

- A sharp cantilever tip scans the surface while a laser and position sensor track deflection.

- Produces height maps and cross‑section profiles from micro‑ to nanoscale.

FIRST DESIGN

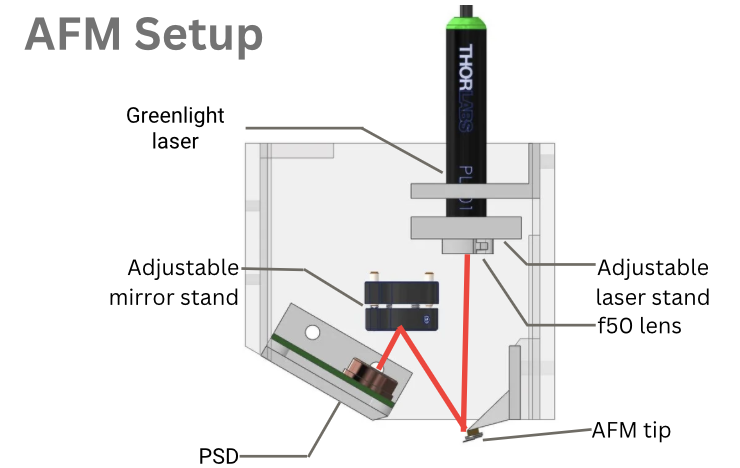

Second(Final) Design

TAPE METHOD OF GRAPHENE

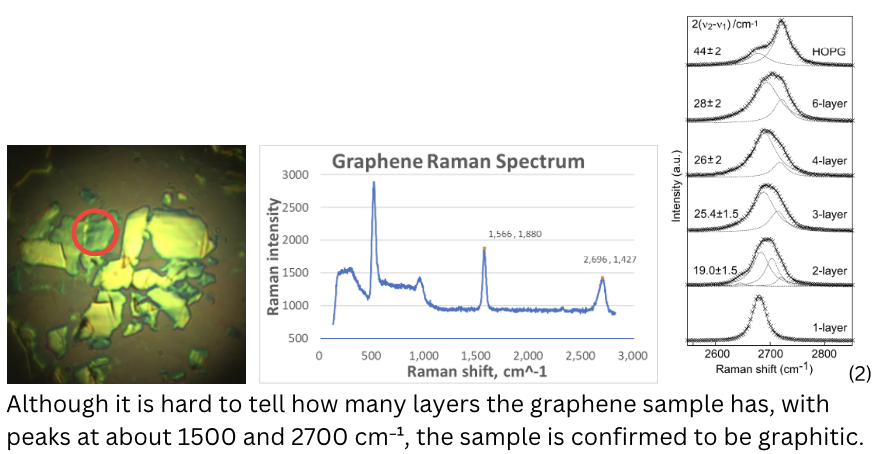

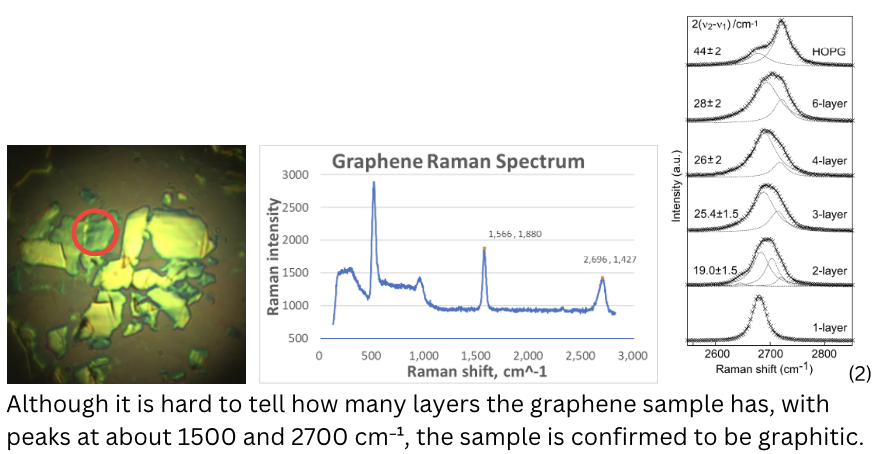

RAMAN SPECTROSCOPY

SCANNING SAMPLES

SUMMARY & RECOGNITION

- Imaged the TGQ1 calibration grating and tape‑exfoliated graphene using a 3D‑printed AFM.

- TGQ1 scans reproduce the expected pattern; graphene scans show identifiable layered regions.

- These results indicate that 3D‑printed structural parts can support nanoscale AFM measurements.

- Bronze Award, Poster Competition.

REFERENCES

- Atomic force microscopy — Wikipedia. Overview of AFM principles.

- Graf, D. et al., Nano Lett. 2007, 7, 242 — Graphene Raman signatures.

← Back to projects